Merino wool has stood the test of centuries — prized for its softness, breathability, and natural performance. Few fibres combine comfort and function so effortlessly.

Fibre perfection

refined by nature

Cloudwool® is spun from premium Australian Merino fibres selected for their exceptional softness, lightness, and structure. Naturally breathable and gentle on the skin, this refined wool offers everyday comfort with a luxurious hand-feel.

UNPARALLELED DEGREE OF

SOFTNESS AND LIGHTNESS

With fibres measuring just 19.5 microns, Cloudwool® delivers an ultra-fine knit that balances warmth and airiness. Its clean finish allows colour to appear crisp and vivid, while its softness makes it ideal for lightweight layers across seasons.

NATURAL MATERIALS THAT MATTER

Our signature fabrics — including Cloudwool®, Alxa Cashmere, Linen and Supple Sheep Suede — are chosen for comfort, structure, and tactile elegance.

Every fibre we select is sourced with intention, offering a balance of breathability, durability, and quiet luxury.

MADE TO LAST

The world doesn’t need another fashion brand—it needs better solutions. In the UK alone, 350,000 tonnes of still-wearable clothing go to landfill each year. Our response? An antidote to mass production and overconsumption.

Sustainability is at the core of everything we do. By crafting timeless, high-quality pieces, we create a wardrobe that transcends seasons and trends, reducing the need for constant replacements.

Style and luxury shouldn’t come at the planet’s expense. With Zomário, they never do.

OUR SUPPLY CHAIN TIERS

GARMENT MANUFACTURING

This is the production step that involves final assembly of the garment before it is delivered to our warehouse. This is where most of the social impacts are felt as it is labour intensive and we have 100% visibility of all the factories working at this stage.

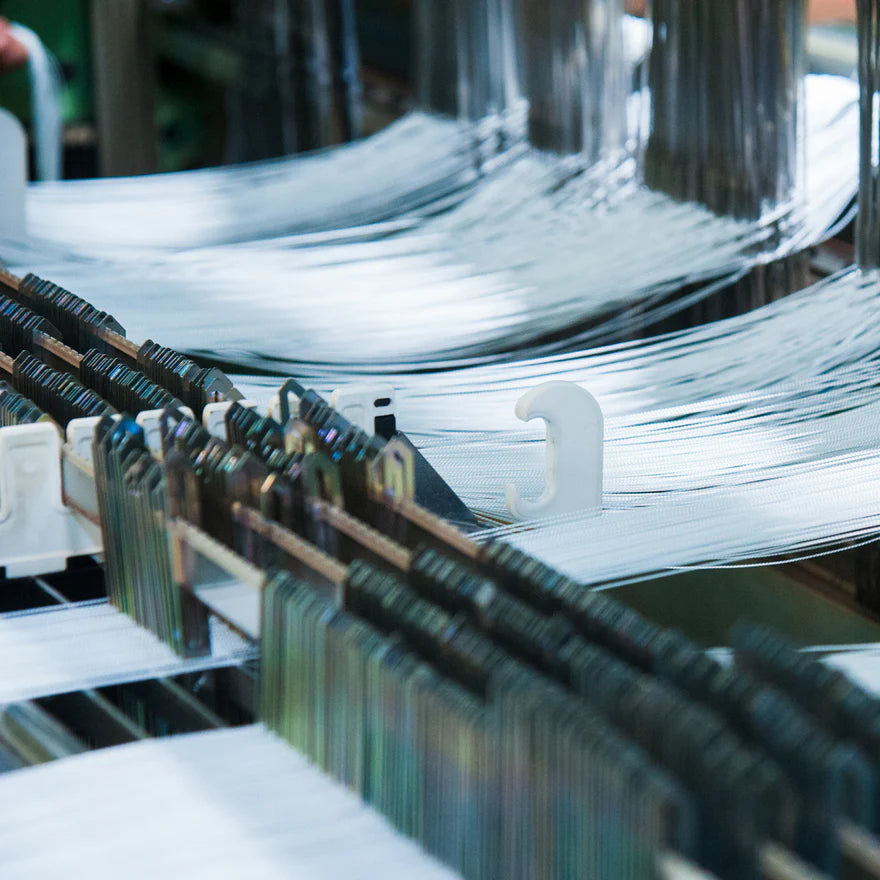

FABRIC MANUFACTURING

This is the fabric production stage including the construction and dyeing of the fabrics and trims. This is usually where most of the carbon intensity is found as large amounts of energy are required forthe production of fabrics.

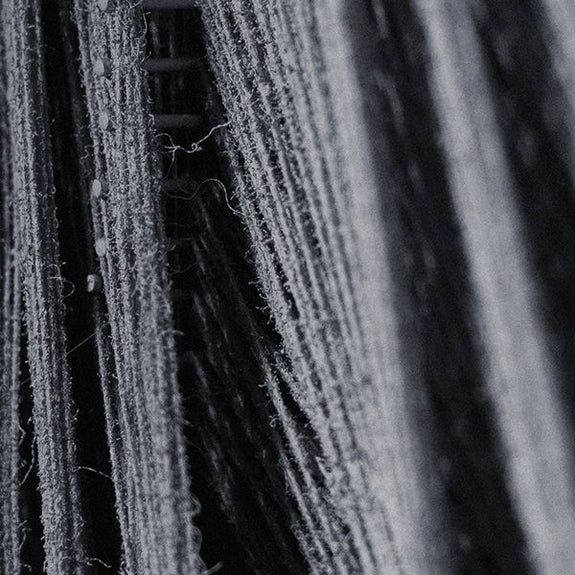

YARN SPINNING

This is where the fibres are spun into yarns, prior to being manufactured into fabrics. This stage is energy intensive and is often done in a unit separate to the tier 2 production. We currently have 47% visibility of the suppliers involved at this stage for our main fabrics.

FIBRE PRODUCTION

Depending on the fibre type, this is where fibres are grown, farmed, or manufactured. It is often very difficult to trace the supply chain to this tier however we currently have 25% visibility of the suppliers involved at this stage for our main fabrics.